After 30 years of development in digital printing, these problems still exist

Time:2022-07-08 From:

The development of digital printing technology in China started from the realization of typing and copying in the 1990s. Although the technology at that time was analog technology and most of the equipment was second-hand, it also explained the beginning of the development of digital printing technology.

30 years of development

The real digital printing appeared after 2000. Driven by the market demand and the supply of new equipment and technology, fast printing shops appeared one after another. At that time, digital printing was not called digital printing, but digital printing. In 2011, the General Administration formulated the "Digital Printing Management Measures" because after 2010, fast printing shops began to chain, processing centers also appeared, Xerox, Canon, Konica Minolta, HP, Ricoh, Ideal and other equipment quality and efficiency Comparable to traditional offset printing machines. After 2016, large-format and digital efficiency equipment appeared, and the application field was greatly expanded. 2019 is the year of inkjet. To be precise, it is the year of domestic inkjet equipment, and the fields of business, books, packaging, and imaging are fully rolled out.

Features & Insufficient

Features

Even though digital printing has been developed for 30 years, many people still don't know the characteristics of digital printing, mainly including small batches printed from one sheet; different personalization of each sheet; customization of exclusive customized large-scale production; on-demand printing may redefine the entire industry chain of flexibility.

Insufficient

From the perspective of the development of digital printing enterprises, there are still problems such as poor basic conditions, unclear development paths, inconsistent information standards, high data risks, and insufficient talent reserves. The road to digital development has a long way to go. "

Digital path

The National Development and Reform Commission and the Central Cyberspace Administration of China released the "Implementation Plan on Promoting the Development of the New Economy by Moving to the Cloud and Using Data to Empower Wisdom", from the digitalization of construction equipment to the digitalization of workshops, factories, enterprises, and the entire industrial chain, and finally The formation of a digital ecology provides a digital path for the industry. In terms of information flow, from a single printing software application to the comprehensive interconnection of the printing integrated management system, break through the information barriers between systems; in terms of data flow, from traditional printing equipment to digital printing equipment, and networked equipment, the full use of networked equipment realizes data flow In terms of business flow, from the consumer-oriented end to the comprehensive construction of the industrial Internet platform, it realizes the connection between the industry and the upstream and downstream of the industry.

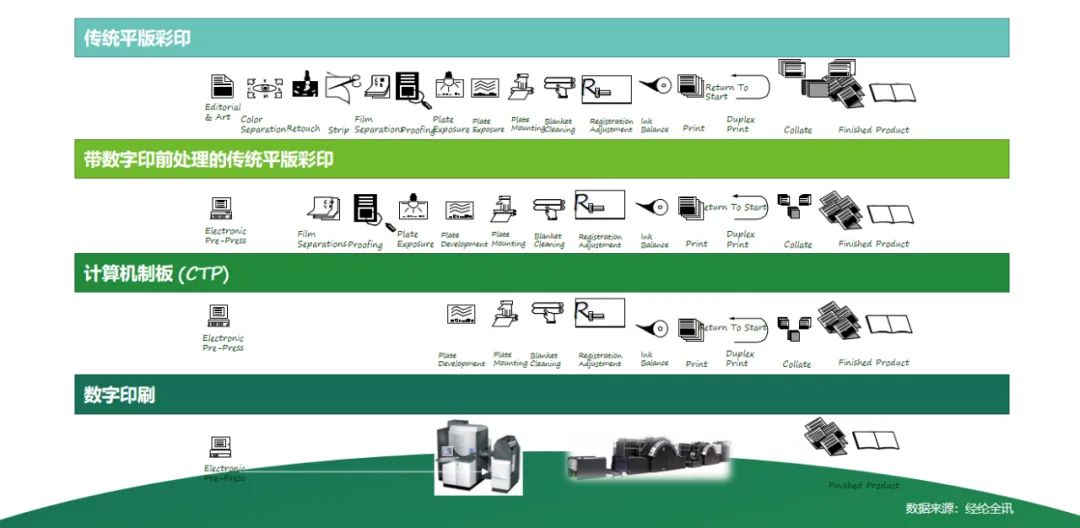

Jinglun Quanxun provides traditional lithographic color printing, traditional lithographic color printing with digital pre-press processing, computer plate making and digital printing process. It wants to explain that the digital printing process is very short, but there is no support for the above-mentioned digitization and information flow, data flow, and business flow. A device is a device.

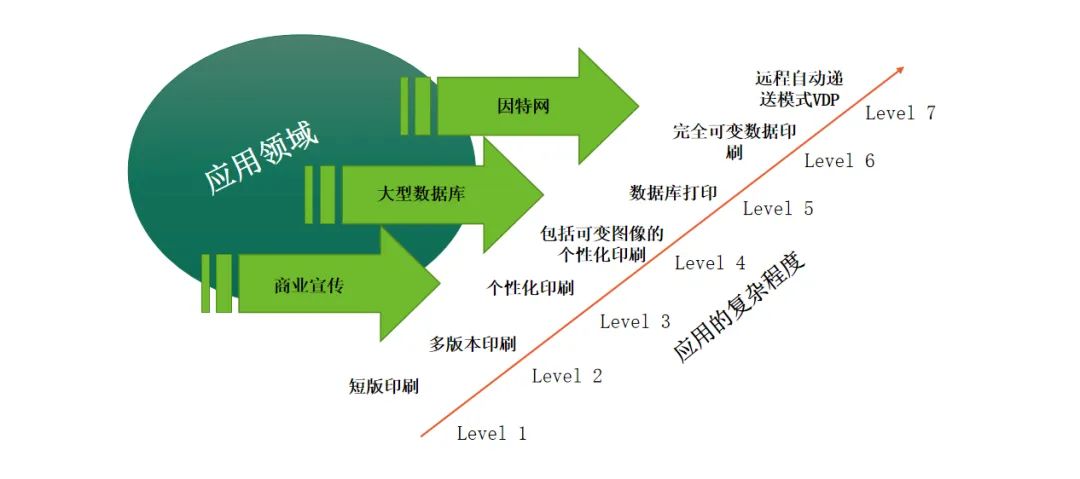

Kodak China’s digital printing application field map in the past clearly shows the complexity of digital printing that can be achieved with the development of technology, from short-run printing for general commercial promotion to remote automatic delivery models using the Internet.

The "From Manual to Non-contact Digital Printing Production Process" provided by Konica Minolta directly shows that non-contact digital printing production is 500% more productive than traditional manual production!